We like to say:

Ideas are easy — execution is everything.

A façade project involves many different parties and stakeholders. Managing these interfaces, even across continents, can be key to project success. You can count on our global experience and interdisciplinary approach to manage the supply and production part of your project.

We have successfully designed, implemented, integrated and operated large robotic systems for façade material manufacturing. For example, for the project 35 Hudson Yards, we integrated an edge-finishing robot into the high-volume production of natural stone panels having a weight of up to 200 kg. It helped significantly to speed up production volume and therefore meeting the timeline and schedules of the curtainwall manufacturer.

Robots offer significant advantages for façade material manufacturers, as we typically deal with large sizes and heavy weights. However, engineering care has to be taken especially on programming topics to allow for sufficient flexibility and on material-flow logistics.

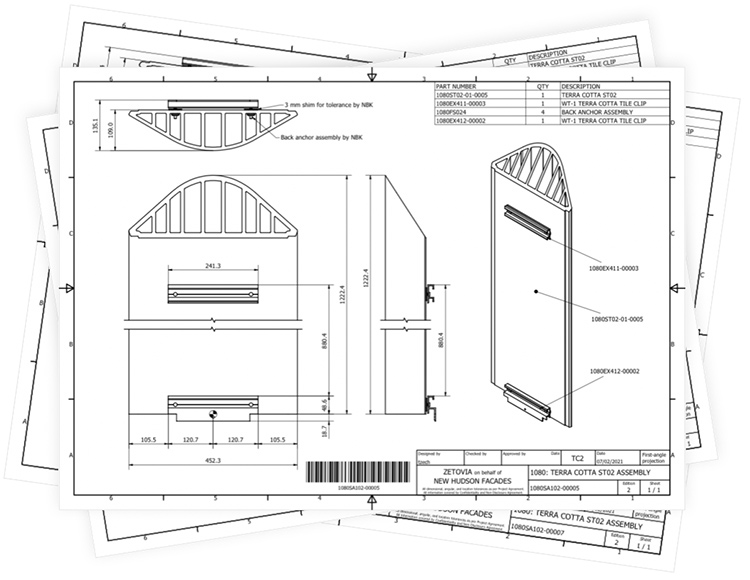

We provide sophisticated design services, such as stone detailing, fixing design, and prototyping. We have a strong focus on digital technologies. And we are engineers — by heart. We never stop thinking how to make things better, more efficient, faster and more sustainable.

We love to engineer novel façade solutions for your project.

No project is like the other, and both materials and the needs and demands of architects are continuously evolving. We have been involved in and leading several façade material development projects in the past, yielding from the development of new finishes and chemical surface treatment processes for natural stone to mechanical surface structuring processes for architectural glass.

Time is of the essence when executing a façade project. However, many projects suffer from poor data interfaces between the different parties involved in the manufacturing of façade materials, curtainwall panels etc. Therefore, approved designs and the corresponding digital data cannot be used directly for CNC manufacturing, element assembly etc., but often will be re-engineered by suppliers and manufacturers to their own standards fitting to their machines and workflows. This process is slow, expensive and error-prone.

ZETOVIA offers to manage product data interfaces between the different stakeholders during façade manufacturing, starting early in the design and engineering process. Obviously, the target is faster and more reliable execution. This doesn’t involve just manufacturing data, but also logistics data in order to track parts properly during the supply process.

Mock-ups are an integral part of a façade project and help architects, owners, façade manufacturers and suppliers to refine design and material choices. Mock-ups are small projects in itself. They require a lot of effort throughout the execution chain, but they can definitely help to make the right, informed choices and decisions. Mock-ups need to be well-thought and organized, with a lot of parties involved at an early project state. This requires intelligent project management and quality control as well as proper documentation. We are here to assist you.

Dry-lays of façade panels are very common in prestigious projects, especially for natural materials such as natural stone. These materials naturally differ in color and texture, which adds a lot to the beauty of the final product. However, it has to be ensured that the materials are to be delivered within the agreed range of color differences and textural features. A dry-lay typically takes place at the manufacturer’s factory (often far away from the construction project itself) and requires significant efforts with regard to time, quality control and documentation.

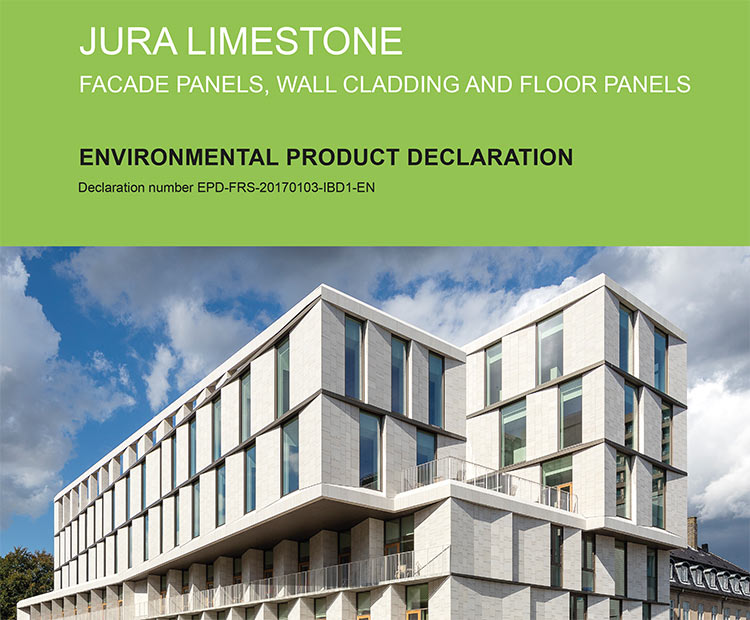

The search for sustainability is definitely one of our main drivers — and has been for many years. Through building materials, today’s buildings carry too much embodied carbon, furthermore, design choices significantly impact the carbon footprint of the building’s operation. For example, among other studies, we initiated and pushed the process for the first third-party verified Environmental Product Declarations (EPD) for natural stone in Europe. EPDs help architects and developers to select the right, sustainable materials and achieve building certifications such as LEED and BREEAM. So let us include scientific sustainability data in the design and material selection process!

The right product at the right place at the right time in the right quality — this is the art of supply chain management. We have been running façade material production for natural stone and architectural glass for several years ourselves. We know what it is like to fulfil the needs of the curtainwall manufacturer and the installer. And we have seen a number of projects struggling or being late because of non-synchronized overseas deliveries. We know you want your project to perform better. We know how to manage supplies — and we might be closer to your supplier than you are. So why not working together?

During pre-construction, many important decisions are taken that directly impact the success of the project. Design alternatives need to be studied, the costs need to be optimized, the feasibility for special solutions needs to be carefully analyzed.Based on our experience with a number of prestigious and large scale projects, we would like to offer our insight to the pre-construction process.

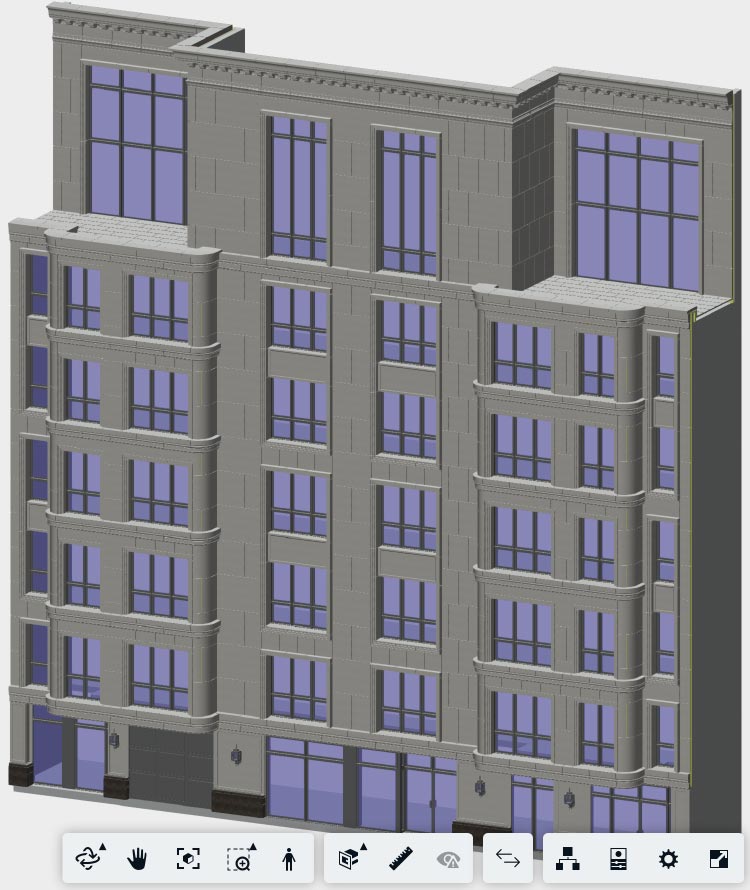

Oftentimes physical and functional essence of any construction project needs to be represented digitally, in a 3D model format. In short, the construction industry is undergoing fundamental changes, not comparable in impact with anything before it, not even with the rise of lean manufacturing in auto-making in the 1980s. An innovative and time-saving tool called Building Information Modeling, or BIM, is the reason for that revolution. BIM technology rapidly enhances complex building processes, shortcutting any project completion date, cutting the expenses and improving the overall quality of the construction. We want clients to understand the incredible advantages that the BIM offers and we want them to get prepared to embrace this technology.

Tell us more about your project. We always appreciate your questions, comments, ideas, and inquiries. Please give us a call or send a short email, we will come back to you shortly. Thank you.